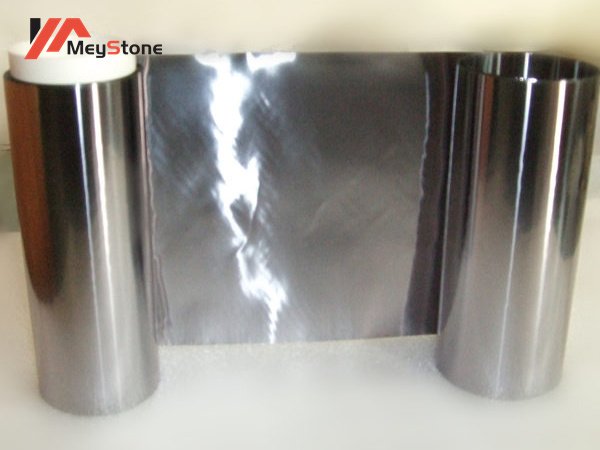

Molybdenum Foil

The surface of our molybdenum foils has silver-gray metallic luster and the density nearly reaches the theoretical density of 10.2g/cm3. Through vacuum annealing, the purity is greater than 3N and conforms to ATM B 386 standard. Our molybdenum foil has great metallic performance and balanced inner structure.

Having relatively smaller coefficient of expansion and the advantage of heat conductivity, molybdenum foils can be processed into thin and tiny parts. Molybdenum foils are commonly used as heat absorbing sink in semi-conductor devices. Molybdenum foils are widely used in illumination, vacuum coating and other electronic components. Molybdenum foils can also be used as the container for metal evaporation in electron microscope labs.

Molybdenum foils are usually used in lamp seals. Because of the unstable expansion rates, lamps should use molybdenum foil to prevent the seals from cracking. Molybdenum foil can be used in UV curing lamps, Quartz Infrared Heat (QIH) lamps and bulbs.

In the field of solar energy, molybdenum foil has a lot of application and research in flexible solar cells. Because molybdenum foil owns linear thermal expansion coefficient similar to sulfur compounds, and also has good electrical conductivity, excellent mechanical properties, high temperature resistance, etc. Compared with other metal substrates, the Iron content is low in the high purity molybdenum foil. So it is not necessary to add a barrier layer between the substrate and the functional layer to avoid the influence of impurities on the electrical properties of the absorption layer. We are professional manufacturer in producing the molybdenum foil for solar energy field. The molybdenum foil can be produced in accord with customer’s demands.